Casing and tubing

Casing and tubing string are the main parts of the well construction.All wells drilled for the purpose of oil or gas production (or injection materials into underground formations)must be cased with marerial with sufficient strength and functionality.

Casing

Casing is the major structural component of a well.Casing is needed to:

● Maintain borehole stability

● Prevent contamination of water sands

● Isolate water from producing formations

● Control well pressures during drilling, production, and workover operations

Casing provides locations for the installation of:

● Blowout preventers

● Wellhead equipment

● Production packers

● Production tubing

Casing strings

There are six basic types of casing strings:

● Conductor Casing

● Surface Casing

● Intermediate Casing

● Production Casing

● Liner

● Liner tieback casing

Conductor casing

Contactor casing is the first string set below the structrai casing .The conductor isolates unconsolidated formations and water sands and protects against shallow gas.This is usually the string onto which the casing head is installed.A dive or a blowout prevention(BOP)stack may be installed onto this string.When cemented,this shring is typically cemnented to the surface or to the mudline in offshore wells.

Surface casing

Surface casing is set to provide blowout protection, isolate water sands, and prevent lost circulation. It also often provides adequate shoe strength to drill into high-pressure transition zones. In deviated wells, the surface casing may cover the build section to prevent keyseating of the formation during deeper drilling. This string is typically cemented to the surface or to the mudline in offshore wells.

Intermediate casing

Intermediate casing is set to isolate:

● Unstable hole sections

● Lost-circulation zones

● Low-pressure zones

● Production zones

It is often set in the transition zone from normal to abnormal pressure. The casing cement top must isolate any hydrocarbon zones. Some wells require multiple intermediate strings. Some intermediate strings may also be production strings if a liner is run beneath them.

Production casing

Production casing is used to isolate production zones and contain formation pressures in the event of a tubing leak.

It may also be exposed to:

● Injection pressures from fracture jobs

● Downcasing, gas lift

● The injection of inhibitor oil

● A good primary cement job is very critical for this string.

Casing a Well

The casing is fabricated in sections, or joints, that are usually about 40 feet long and screwed together to form longer lengths of casing, called casing strings. Each end of the casing joint has male threads that are protected by cap called a thread protector until the casings are ready to be jointed. Then, a collar or coupling, composed of a short cylindrical steel pipe that is slightly larger in diameter than the joints and also has female threads, is used to connect the two male joint ends. A thread compound is used on the two ends to ensure a tight seal.

Casing is run from the rig floor, connected one joint at a time by casing elevators on the traveling block and stabbed into the previous casing string that has been inserted into the well. Hanging above the drill floor, casing tongs screw each casing joint to the casing string. Casing is run into the well and officially landed when the weight of the casing string is transferred to the casing hangers, which are located at the top of the well and use slips or threads to suspend the casing in the well.

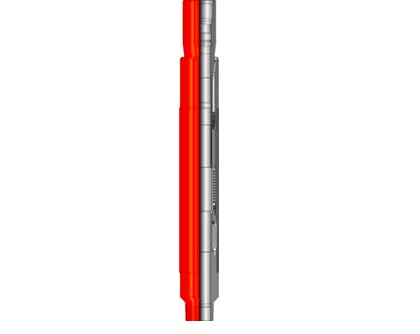

The introduce of pup-joint

We also supply permium thread products by customer's request:

● Size: tubing coupling from 1.9" to 4-1/2",Casing coupling fro4-1/2"to 13-3/8"

● Type: NU, EU(tubing coupling), STC,LC,BTC(casing coupling).

● Surface treatment: Whole phosphating, or inside phosphating and outside coating

● Packing: By carton, wooden case, wooden pallet, or by requirements of customers

● Grade:J55, K55, N80-1, N80-Q, L80, C90, P110

Tubing Pup Joint Main Technical Specification

Tubing Joint

Size Type of Thread O.D*L(mm)

2-3/8" NUE 73.02*107.95

2-3/8" EUE 77.80*123.82

2-7/8" NUE 88.90*130.18

2-7/8" EUE 93.17*130.35

3-1/2" NUE 107.95*142.88

3-1/2" EUE 114.30*146.05

4" NUE 120.65*146.05

4" EUE 127.00*152.40

4-1/2" NUE 132.08*155.58

4-1/2" EUE 141.30*158.75

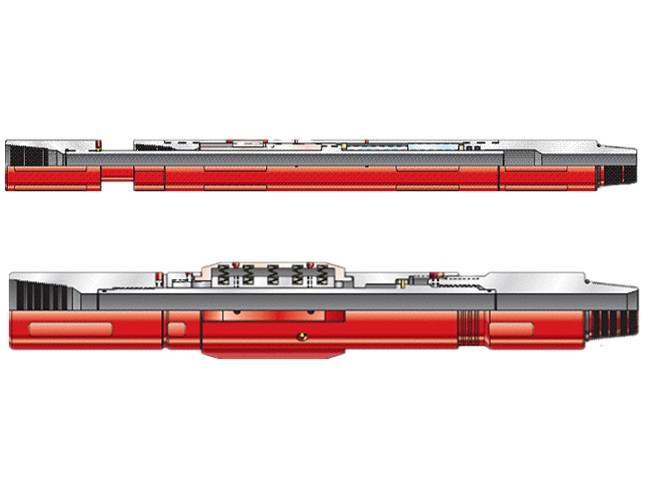

Casing &Tubing Coupling

Description

Coupling is an API threaded tubular section of steel pipe used in connecting two pipe joints together. Structurally, they are short lengths of heavy wall pipe with similar type of box threads on each end.Tubing coupling is a type of drilling tool used in oil field. It

is mainly used for connecting oil pipes. This pipe coupling has solved the problem that the existing couplings tend to crack due to stress

concentration. The oil pipe ends and the inner wall of the steel coupling are connected through threads. The ends of the coupling and the oil pipe have the same type of threads. This type of connection is not easy to

crack and the connection effect is good. The tubing coupling can

effectively avoid the oil well string dropout accident.

Pipe coupling is a very short pipe or tube used for connecting two oil

pipes.It has a socket at one or bpth ends which allow two oil pipes to be jointed, welded, brazed or soldered (copper, brass ect.) together.If the two ends of a coupling are different, then it is usually referred to as an

adapter. These pipe couplings include casing coupling and tubing coupling.

Properties

●This pipe coupling is used to connet two oil pipes.

●This thread patterns of the steel coupling include nonupset thread (NUE) and upset thread (EUE)

●Outer diameter of the tubing coupling ranges from 55.88mm to141.3mm 1.9"~4 1/2")

●Materials of this product include H40, J55, N80-1, N80Q, L80, C90,T95, and P110

Advantages

●This product has passed ISO9001 quality system assessment and the API certification from the American Petroleum Institute.

●Our commpay manufactures these steel coupling according to the latest sandards of API 5CT specification. The ex factory pass rate of the product reaches 100%.

●The pipe couplings have plain or upset ends.

●This product festures corrsion resistance, high efficiency, and good

durablity.

●The tubing coupling are avaliable in various speifications.

Application

●The steel coupling is mainly used to connect oil pipes in pil drilling.

●This product can be used to connect the shafts of units that are

manufactured separately.

●It can fit the misalignment of the shafts or introduce mechanical flexibility.

●The pipe coupling is capable of reducing the transmission of shock losds from one shaft to another.

●It can also introduce protecyion against overloads.

●The steel coupling can be used to alter vibration characteristics of

rotating units.

●Pipe coupling is also used to connect driing par and driven part.